Carpenters, woodworkers, blacksmiths, masons, and even home enthusiasts need a solid pair of chisels. Many individuals use them for do-it-yourself projects, sculpting, and other types of crafting. If you want to deal with metal, though, you can't just use any old chisel. They're not built for that. A cold chisel is what you need to cut into and shape metal. These particular chisels have a bevelled edge and can cut through any metal that is softer than the material they are composed of.

So, if you're wanting to buy a set of cold chisels, we've compiled a list of the best cold chisels of 2022 for you to peruse and choose your favourite product. In addition, our buying guide will lead you through all you need to know before making your choice.

What Exactly Are Cold Chisels?

Before we get into what you need to know before purchasing a cold chisel, let's define what a cold chisel is. A cold chisel, unlike a wood chisel, is specifically designed to chisel or cut through cold, hard metals. They're specifically engineered to work with metals that are softer than the ones they're made of.

Click for more: WORKPRO COLD CHISEL

These chisels are forged from tempered and hardened steel and have an octagon-shaped handle with a bevelled cutting edge. They are not heated with heat torches, forges, or other comparable processes. Because these tools are intended for use with metals, they have a broader angle than a woodworking chisel's blade, allowing them to cut through metal more easily but not being as sharp as a woodworking chisel.

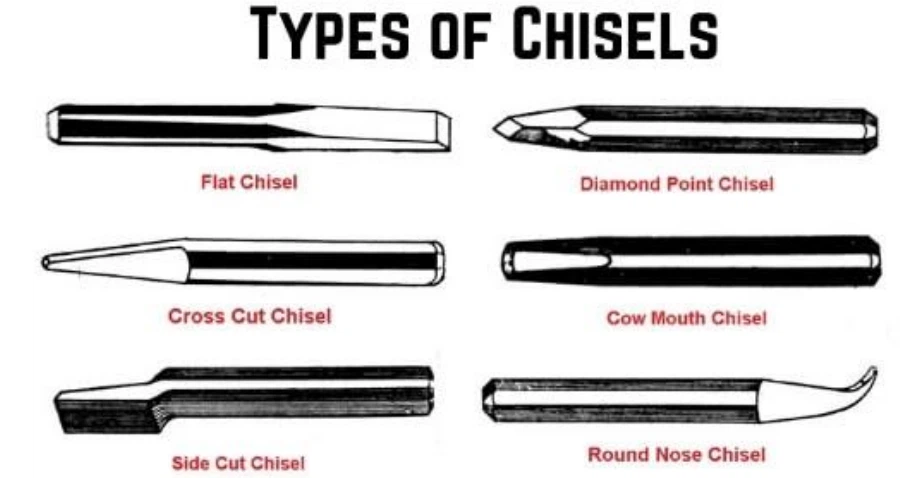

What Kinds of Cold Chisels Are There?

1. Flat chisels

These chisels are frequently used for cutting and shaping bars and rods. They are also used to cut and smooth the surfaces of some sheet metals.

2. Cross out the chisel

These tools, which have a small blade behind the cutting edge of the chisel, are intended for shaping and cutting grooves and slots.

3. Round nose chisel

Round nose chisels are specifically intended to operate with semi-circular grooves in bearings for oil routes.

4. Diamond point chisel

The form of this cold chisel is quite beneficial for removing undesired trash and materials from corners, nooks, and other challenging spots.

5. Cow Mouth Chisel

It has the shape of a cow's largemouth in these types of chisels. That is why it is referred to as a cow mouth chisel. It is used to make the edges of projecting pieces of plain metal, rivet heads, and large circular holes. Its forging angle is slanted.

6. Side Cut Chisel

Side-cut chisels are employed in situations where other types of chisels are difficult to use. This chisel is used to clean the keyway and cotter way.

What Should You Consider Before Purchasing a Cold Chisel?

- Construction quality

When it comes to how well the tool functions and last, the build quality of your chisel makes all the difference. A good cold chisel forges its sharp edge with a combination of carbon and steel. There are also vanadium steel choices paired with stronger carbon possibilities, although they are more expensive. There are other chisels composed of steel and manganese that function well in absorbing impact. Using a chisel with any of these combos almost always implies you're getting an excellent item.

- Built to last

Cold chisels and chisels in general must be incredibly resilient. A good cold chisel should not only be able to withstand blows from a mallet or hammer but also have a sharp enough edge to cut and carve metal effectively.

- Comfort

If you have ever worked with chisels, you understand how crucial it is that they are comfortable to hold. With a comfortable grip, you may carve and sculpt your works with greater accuracy and for longer periods without becoming fatigued.

How Should a Cold Chisel Be Used?

Ensure that you have a proper grip on the chisel's handle for proper use. To accomplish this, create a fist around the handle while keeping your thumb and forefinger about an inch from the top. Make sure your grip is not too tight, as a grip that is too tight will transfer more force than intended while using a hammer.

Now that you have a firm grip on the chisel, take care not to speed up the carving process. A constant rhythm of hammer blows on the chisel, as opposed to a single powerful stroke, will ensure that no errors are made and the metal is cut with flawless precision.

PEOPLE ALSO ASKED

Q: Can a cold chisel be utilized for stonework?

A: No, cold chisels are not intended for usage with masonry. Using these instruments for a purpose other than working with metals would be ineffective.

Q: Do I need to wear protective gear when using a cold chisel?

A: When working with a cold chisel, you should always wear some form of eye protection. If necessary, safeguards are not taken, metal shavings can cause severe injuries during carving.

Q: How do I properly handle a cold chisel?

A: Hold a cold chisel in your fist firmly, but not too tightly, as this will allow more hammer force to be transferred to the chisel.

WeChat: 13429631398

WeChat: 13429631398